Contact Us

Address: No.4 Xuesong Rd, Hi-New Technology Industry Development Zone, Zhengzhou City, Henan Province, P. R. China,450001

Tel/Whatsapp: 86-13700884564

E-mail: [email protected]

Tel/Whatsapp: 86-13700884564

E-mail: [email protected]

CSP04 Vane Type Pump

vane type pump

Products Configuration

Technical Parameters

Advantages

Options

Comments

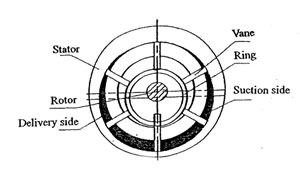

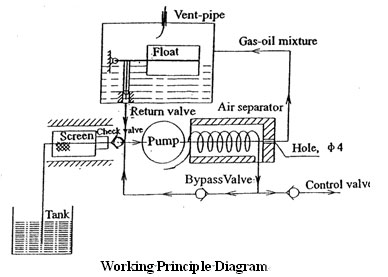

| a. The rotor of the pump is rotated clockwise by the motor, and the vanes are rotated together with ring in the same direction. The rotor and the casing are eccentric with each other. Because of the eccentricity, the volume enclosed in the rotor, vane and inside wall of the casing is changed as the rotor rotates, vane type pump and the oil is moved consequently. b. A strainer is installed to the suction to prevent foreign substances from entering the pump and piping, and a check valve is installed to prevent the oil in the pump from returning to the tank. c. The oil sent out of the pump is sent to air separator. Because of the flow guide, the oil is sent along the casing of the air separator in the method of spiral mode of motion. The low density gas-oil mixture is sent through the center(Hole, φ4 )of discharge header to the normal pressure chamber. d. The separated air is released through vent-pipe from the top of the atmospheric chamber into the atmosphere. e. The oil discharged through the φ4 hole accumulates in the atmospheric chamber. If the oil reaches a certain level, the float is floated to open the valve, then the oil is returned to the suction side. f. The control valve consists of main valve and auxiliary valve. The main valve on the discharge side is kept open by the oil pressure while the oil is nozzle pump being supplied. When the nozzle is closed , this main valve is closed automatically to prevent the oil in the hose and flow meter from flowing back. This main valve also holds the oil pressure in the hose and flow meter while the operation is stopped to protect the flow meter from being rotated when the oil is supplied next time. g. When the pressure rises to a certain value due to change of ambient temperature, the auxiliary valve vane type pump opens to vacume pump release an abnormal pressure caused by the thermal expansion of oil. h. The discharge side of the casing is equipped with nozzle pump a bypass valve which is used to circulate the oil through the pump when the nozzle is closed or the oil is supplied at a low speed. The discharge pressure can be adjusted with a spring. | |

| |

| |

| Adjustment of set pressure of pump | |

| If the discharging flow rate is too low because of higher suction head and longer piping, etc., and the discharge pressure of pump is unstable, the discharge pressure(the nozzle is closed) and inlet vacuum pressure(the nozzle is kept open) must be inspected. There are 1/4b. When installing or dismantling pressure gauge and vacuum pressure gauge, stop the pump. The set pressure of vacume pump has been adjusted to 0.18~0.20Mpa with the nozzle closed when the pump left factory. If the measured pressure does not according with the set pressure and the adjustment of bypass valve is needed, please adjust the bypass valve when the pump is not rotated. 1) Loose cap nut. 2)Adjust the set pressure by turning the adjusting bolt: ·Turning clockwise: set pressure heightened. ·Turning counterclockwise: set pressure lowered. 3) After adjusting set pressure, tighten cap nut. 4) Take care not to screw the adjusting bolt excessively to lock valve. If the valve is locked. |